MS-G / MSP-G series

– No tool is needed for blade replacement.

– Blade can be replaced easily and quickly.

– Blade opening-angle can be adjusted. (excepting for MS3G type)

-

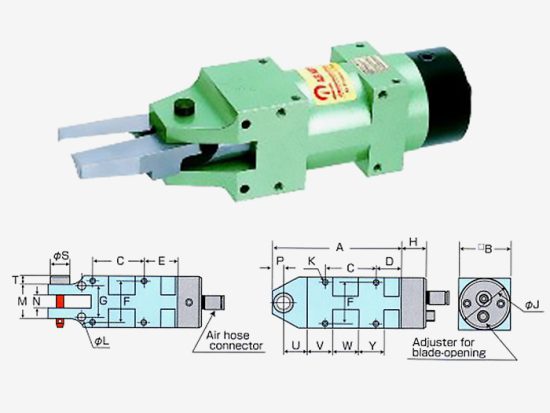

MS….G type (Standard)

Standard Square type – Machine mounting type

-

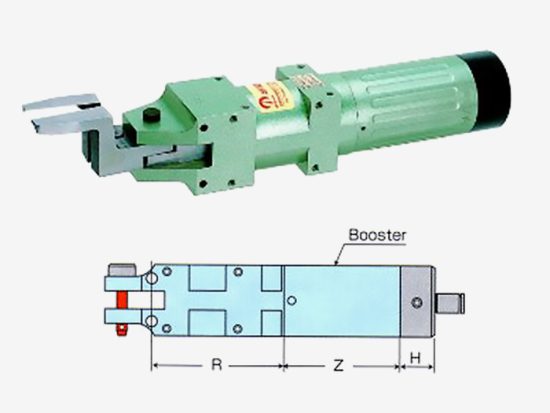

MSP….G type (Heavy-duty)

Heavy-duty Square type – Machine mounting type

MS-G specification / Blade cutting capacity (Фmm)

| Model (less blade) |

Weight (g) |

Airconsumption (cm3/stroke) |

Power N (approx.) |

Air pressure (MPa) |

Blades (*)Carbide tipped |

Copper wire |

Steel wire |

Stainless wire |

Pino wire |

Crimping | Plastic | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Soft | Hard | |||||||||||

| MS3G | 75 | 31 | 773 | 0.4 – 0.5 | S20, S20S, CR20, EP20 | 0.8 | 0.4 | – | – | – | – | – |

| Z20*, Z20S, ZCR20, ZEP20 | 0.8 | 0.4 | 0.2 | 0.2 | – | – | – | |||||

| F10, F10S, FD10, FEP20 | – | – | – | – | – | 1.0 | – | |||||

| MS5G | 141 | 56 | 842 | 0.4 – 0.5 | S2, S2S, CR2, EP2 | 1.0 | 0.5 | – | – | – | – | – |

| Z2*, Z2S, ZCR2, ZEP2 | 1.0 | 0.5 | 0.3 | 0.3 | – | – | – | |||||

| F1, F1S, FD1, FEP2 | – | – | – | – | – | – | – | |||||

| MS10G | 254 | 105 | 1,493 | 0.4 – 0.5 | S4, S4S, CR4, EP4 | 1.6 | 1.0 | – | – | – | – | – |

| Z4*, Z4S, ZCR4, ZEP4 | 1.6 | 1.0 | 0.5 | 0.5 | – | – | – | |||||

| F3, F3S, FD3, F3LS, FEP4 | – | – | – | – | – | 4.0 | 2.6 | |||||

| Y4 | – | – | – | – | – | – | – | |||||

| MS10AG | 248 | 122 | 1,879 | 0.4 – 0.6 | S5A, S5AS, CR6A, EP6A | 1.8 | 1.2 | 1.0 | – | – | – | – |

| Z6A*, ZCR6A, ZEP6A | 1.8 | 1.2 | 1.0 | 0.5 | – | – | – | |||||

| F5A, F5AS, FD5A, FEP6A | – | – | – | – | – | 4.0 | 2.6 | |||||

| Y6A | – | – | – | – | – | – | – | |||||

| MS20G | 425 | 268 | 3,490 | 0.5 – 0.6 | S5, S5S, P6, CR6, EP6 | 2.6 | 2.0 | 1.6 | – | – | – | – |

| Z6, Z6S, ZCR6, ZEP6 | 2.6 | 2.0 | 1.6 | 1.0 | – | – | – | |||||

| F5, F5S, FD5, F5LS, FEP6 | – | – | – | – | – | 7.0 | 5.0 | |||||

| Y6, K6 | – | – | – | – | – | – | – | |||||

| MS30G | 788 | 631 | 5,531 | 0.5 – 0.6 | S7P, S7PS, P8P, CR8P, EP10P, P8PS | 3.3 | 2.8 | 2.0 | – | – | – | – |

| Z8P*, Z8PS, ZCR8P, ZEP10P | 3.3 | 2.8 | 2.0 | 1.2 | – | – | – | |||||

| F9P, F9PS, FD9P, FEP10P | – | – | – | – | – | 10.0 | 5.0 | |||||

| Y8P, K8P, Y817P | – | – | – | – | – | – | – | |||||

| SH8P | – | – | – | – | – | – | – | |||||

| A8P-1.25, A8P-2.0 | – | – | – | – | 1.25/2.0 | – | – | |||||

| AR8P-1.25, AR8P-2.0 | – | – | – | – | 1.25/2.0 | – | – | |||||

| Model (less blade) |

A (mm) |

B (mm) |

C (mm) |

D (mm) |

E (mm) |

F (mm) |

G (mm) |

H (mm) |

J (mm) |

K (mm) |

L (mm) |

M (mm) |

N (mm) |

P (mm) |

R (mm) |

S (mm) |

T (mm) |

U (mm) |

V (mm) |

W (mm) |

Y (mm) |

Z (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MS3G | 89 | 20 | 40 | 19 | 24 | 16 | 14 | 12 | 20 | M3 | 3.3 | 20 | 7 | 7 | 71 | 11 | 5 | 3 | 25 | 25 | 15 | – |

| MS5G | 74 | 30 | 30 | 14 | 19 | 24 | 18 | 15 | 30 | M3 | 4.3 | 20 | 7 | 7 | 54 | 11 | 5 | 13 | 15 | 15 | 15 | – |

| MS10G | 93 | 36 | 30 | 18 | 23 | 28 | 28 | 24 | 36 | M4 | 4.3 | 23 | 9 | 7 | 65 | 11 | 5 | 16 | 27 | 15 | 15 | – |

| MS10AG | 93 | 36 | 30 | 18 | 23 | 28 | 28 | 24 | 36 | M4 | 4.3 | 26 | 12 | 7 | 65 | 11 | 5 | 16 | 27 | 15 | 15 | – |

| MS20G | 109 | 45 | 40 | 19 | 24 | 36 | 30 | 27 | 45 | M4 | 5.3 | 26 | 12 | 9 | 81 | 11 | 5 | 15 | 31 | 25 | 15 | – |

| MS30G | 150 | 56 | 60 | 20 | 30 | 46 | 40 | 27 | 56 | M5 | 5.3 | 36 | 17 | 15 | 110 | 12 | 5 | 20 | 41 | 38 | 22 | – |

MSP-G specification / Blade cutting capacity (Фmm)

| Model (less blade) |

Weight (g) |

Airconsumption (cm3/stroke) |

Power N (approx.) |

Air pressure (MPa) |

Blades (*)Carbide tipped |

Copper wire |

Steel wire |

Stainless wire |

Pino wire |

Crimping | Plastic | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Soft | Hard | |||||||||||

| MSP3G | 111 | 48 | 1,090 | 0.3 – 0.4 | S20, S20S, CR20, EP20 | 0.8 | 0.4 | – | – | – | – | – |

| Z20*, Z20S, ZCR20, ZEP20 | 0.8 | 0.4 | 0.2 | 0.2 | – | – | – | |||||

| F10, F10S, FD10, FEP20 | – | – | – | – | – | 1.0 | – | |||||

| MSP5G | 205 | 94 | 1,234 | 0.3 – 0.4 | S2, S2S, CR2, EP2 | 1.0 | 0.5 | – | – | – | – | – |

| Z2*, Z2S, ZCR2, ZEP2 | 1.0 | 0.5 | 0.3 | 0.3 | – | – | – | |||||

| F1, F1S, FD1, FEP2 | – | – | – | – | – | 2.0 | – | |||||

| MSP10G | 369 | 174 | 2,099 | 0.3 – 0.4 | S4, S4S, CR4, EP4 | 1.6 | 1.0 | – | – | – | – | – |

| Z4*, Z4S, ZCR4, ZEP4 | 1.6 | 1.0 | 0.5 | 0.5 | – | – | – | |||||

| F3, F3S, FD3, F3LS, FEP4 | – | – | – | – | – | 4.0 | 2.6 | |||||

| Y4 | – | – | – | – | – | – | – | |||||

| MSP10AG | 366 | 209 | 2,750 | 0.4 – 0.5 | S5A, S5AS, CR6A, EP6A | 1.8 | 1.2 | 1.0 | – | – | – | – |

| Z6A*, ZCR6A, ZEP6A | 1.8 | 1.2 | 1.0 | 0.5 | – | – | – | |||||

| F5A, F5AS, FD5A, FEP6A | – | – | – | – | – | 4.0 | 2.6 | |||||

| Y6A | – | – | – | – | – | – | – | |||||

| MSP20G | 648 | 373 | 5,373 | 0.4 – 0.5 | S5, S5S, P6, CR6, EP6 | 2.6 | 2.0 | 1.6 | – | – | – | – |

| Z6, Z6S, ZCR6, ZEP6 | 2.6 | 2.0 | 1.6 | 1.0 | – | – | – | |||||

| F5, F5S, FD5, F5LS, FEP6 | – | – | – | – | – | 7.0 | 5.0 | |||||

| Y6, K6 | – | – | – | – | – | – | – | |||||

| MSP30G | 1.115 | 1,146 | 10,118 | 0.5 – 0.6 | S7P, S7PS, P8P, CR8P, EP10P, P8PS | 3.3 | 2.8 | 2.0 | – | – | – | – |

| Z8P*, Z8PS, ZCR8P, ZEP10P | 3.3 | 2.8 | 2.0 | 1.2 | – | – | – | |||||

| F9P, F9PS, FD9P, FEP10P | – | – | – | – | – | 10.0 | 6.5 | |||||

| Y8P, K8P, Y817P | – | – | – | – | – | – | – | |||||

| SH8P | – | – | – | – | – | – | – | |||||

| A8P-1.25/2.0/5.5, A8WP-1.25-2.0/2.0-5.5 | 1.25/2.0/5.5 | – | – | |||||||||

| AR8P-1.25/2.0/5.5, AR8WP-1.25-2.0/2.0-5.5 | 1.25/2.0/5.5 | – | – | |||||||||

| Model (less blade) |

A (mm) |

B (mm) |

C (mm) |

D (mm) |

E (mm) |

F (mm) |

G (mm) |

H (mm) |

J (mm) |

K (mm) |

L (mm) |

M (mm) |

N (mm) |

P (mm) |

R (mm) |

S (mm) |

T (mm) |

U (mm) |

V (mm) |

W (mm) |

Y (mm) |

Z (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MSP3G | 89 | 20 | 40 | 19 | 24 | 16 | 14 | 12 | 20 | M3 | 3.3 | 20 | 7 | 7 | 71 | 11 | 5 | 3 | 25 | 25 | 15 | 61 |

| MSP5G | 74 | 30 | 30 | 14 | 19 | 24 | 18 | 15 | 30 | M3 | 4.3 | 20 | 7 | 7 | 54 | 11 | 5 | 13 | 15 | 15 | 15 | 50 |

| MSP10G | 93 | 36 | 30 | 18 | 23 | 28 | 28 | 24 | 36 | M4 | 4.3 | 23 | 9 | 7 | 65 | 11 | 5 | 16 | 27 | 15 | 15 | 71.5 |

| MSP10AG | 93 | 36 | 30 | 18 | 23 | 28 | 28 | 24 | 36 | M4 | 4.3 | 26 | 12 | 7 | 65 | 11 | 5 | 16 | 27 | 15 | 15 | 71.5 |

| MSP20G | 109 | 45 | 40 | 19 | 24 | 36 | 30 | 27 | 45 | M4 | 5.3 | 26 | 12 | 9 | 81 | 11 | 5 | 15 | 31 | 25 | 15 | 87 |

| MSP30G | 150 | 56 | 60 | 20 | 30 | 46 | 40 | 27 | 56 | M5 | 5.3 | 36 | 17 | 15 | 110 | 12 | 5 | 20 | 41 | 38 | 22 | 92 |