SH-3510 + SF-3110

A blade that best suits your work requirements can be designed. This cutter is ideal for up-and-down push cutting (guillotine system) and punching.

Oscillator:SH-3510

Upgraded: Connection with PLC is now available

Factory improvement through DX/IoT requires connection with various

controllers and connection with PLC is now available besides the conventional relay control by ON/OFF switching. Standard installation of analog signal output for the load/amplitude and additional digital signals for each oscillation frequency/error type allow outputting more detailed data now. Moreover, receiving overloads/operation logs (is) now available by connecting with our options, this allows us to check the points to be concerned or the details of a problem using the connected PC(Telecommunications standard: CC-Link IE or Profinet)

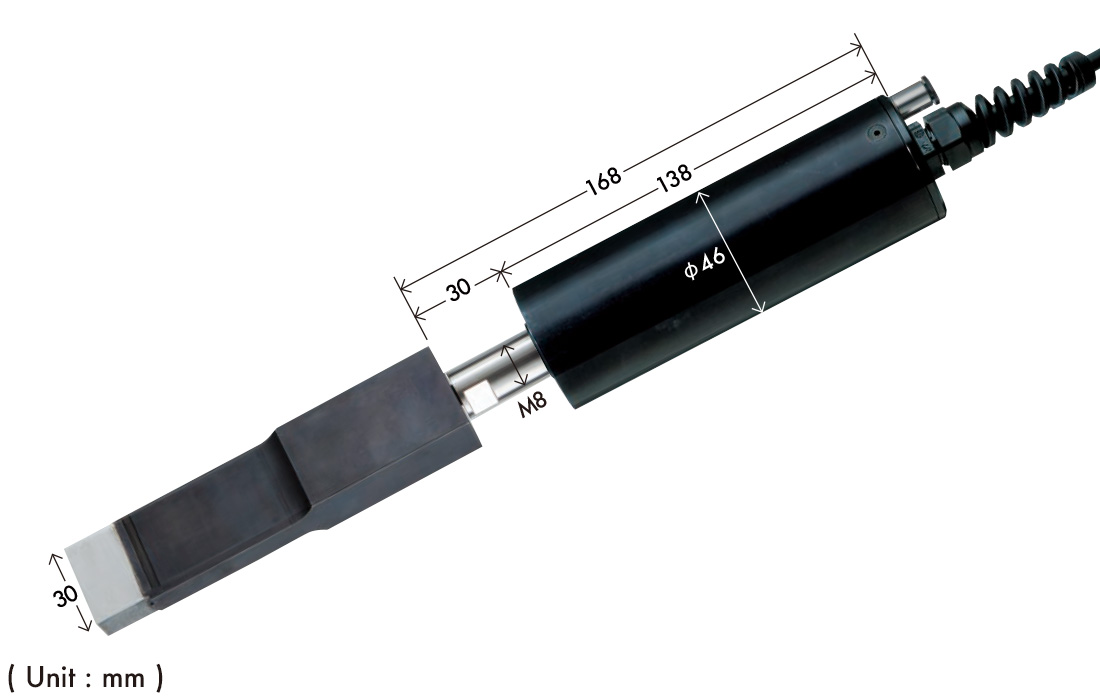

Transducer:SF-3110

The main body of the transducer is a cylindrical duralumin case that is easy for mounting on automated machinery. The blade width can be selected according to applications, which enables to design the blade that fits the profile of the article to be machined. Particularly, the transducer is best fit to up-and-down push cutting (guillotine system) and punching.

-

SH-3510

Oscillator

- Frequency adjustment

- Auto-tracking type

- Max. output power

- 500W

- Output adjustment

- Step-less continuously variable type

- Power supply

- Single phase 200VAC, 50/60Hz

- Power consumption

- 1000VA

- Outer dimension (mm)

- 300(W) x 400(D) x 200(H)

- Weight

- 11kg

-

SF-3110

Transducer

- Frequency

- 20kHz

- Vibration element

- PZT piezoelectric transducer

- Housing material

- Aluminum alloy

- Cord length

- 4M (maximum extension: 10M)

- Outer dimension

- φ116/φ46×168.5L(mm)

- Weight

- 600g

Applicable materials

- plate, sheet, film, and laminated material

- boron, kevlar, polyethylene fiber, etc.

- Food processing

- vulcanized latex, non-vulcanized latex, sheeting material, and tube

-

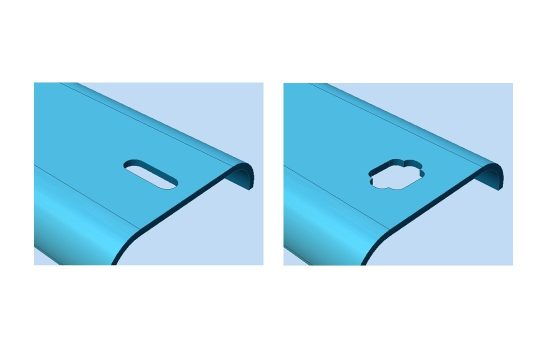

Blade tool

Option

-

Punching sample