News List

-

We now have the serious parts shortage such as the semiconductors and electronic parts due to the recent global supply chain issues.

We have been working hard to secure the parts and furthermore, we have endeavored to provide stable provision of our products, such as conversion to alternative parts and probably holding inventory but we found that the following models would continue to be difficult to manufacture. we regret to say that we will temporarily suspend the sale of the following models.

SONOFILE SF-355ULTRAFORM UF-0101

We apologize for any inconvenience caused to our customers and distributors, and thank you very much in advance for your understanding. At the moment, the timing of resale is undecided.

Stable Supply of UF-0103 and ST-360

Argofile stably offers you the Ultrasonic Polishing Machine UF-0103 and ST-360 continuously, and we appreciate your continued patronage very much.

Argofile Japan LimitedDear valued customer,

We will close our office from December 28, 2021 to January 5, 2022 due to our Year-end and New Year holidays.

Any inquiries/orders received during the closure will be responded to on January 6th, 2022.

We would appreciate your understanding.

Best regards,

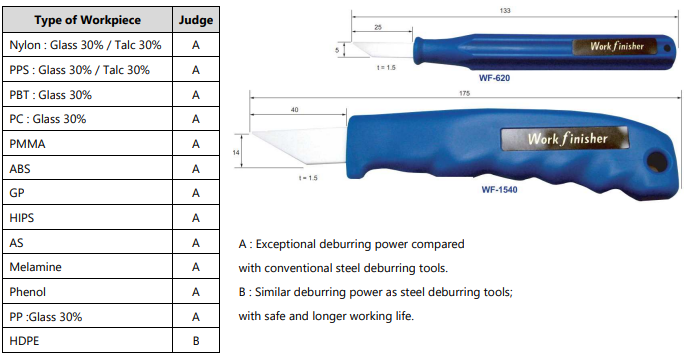

Workfinisher

Ceramic Deburring Tool Series

Workfinisher WF-1540 & WF-620

The blade of Work finisher is made of Zirconia ceramic which has the second highest hardness after diamond. Therefore, Workfinisher is the ideal product for deburring the molded parts made of the hard plastics containing talc, carbon fiber and glass filled resin.

Furthermore, it is suitable for deburring and chamfering non-ferrous metal such as the copper, aluminum and brass. As the advantage, it is Rust less, Wear resistance, Non-magnetic, Chemical resistance and Very safe No sharp edge.

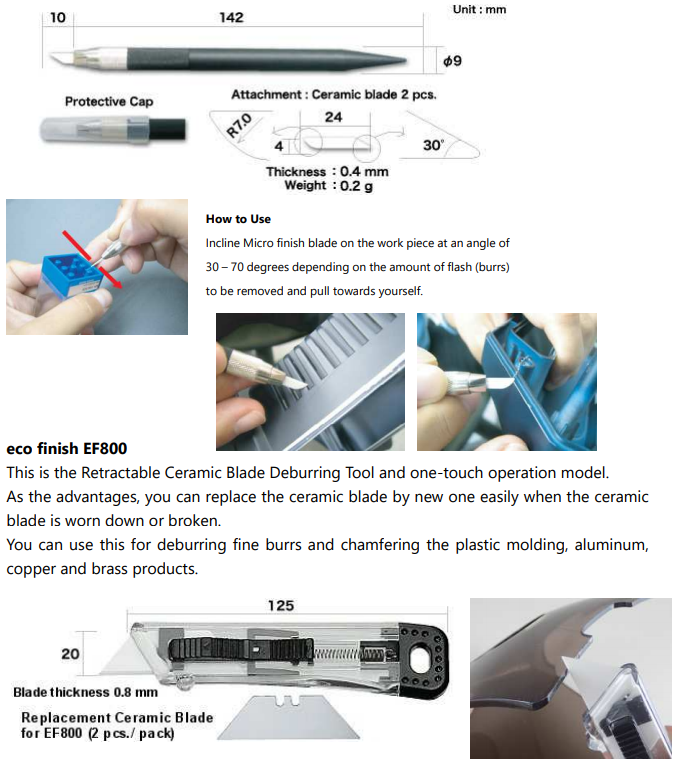

Micro finish MF400

This is the Precision Ceramic Blade Deburring Hand Tools and It is suitable for deburring the thin walled part and fine burrs without the fear of cutting your hand or fingers in the process. It is ideal for curved and complicated shapes, excels on ultra hard resins like glass-fiber carbon fiber and talc filled plastics.

eco finish EF1200

This is Snap-Off Ceramic Blade Deburring Tool and you can use it for a long time because even if the ceramic blade is worn down, you can use it continuously by breaking each blade along the groove on the ceramic blade. So you can use it like the utility knife or box cutter but very safe.

You can use this for deburring fine burrs and chamfering the plastic molding, aluminum, copper and brass products.

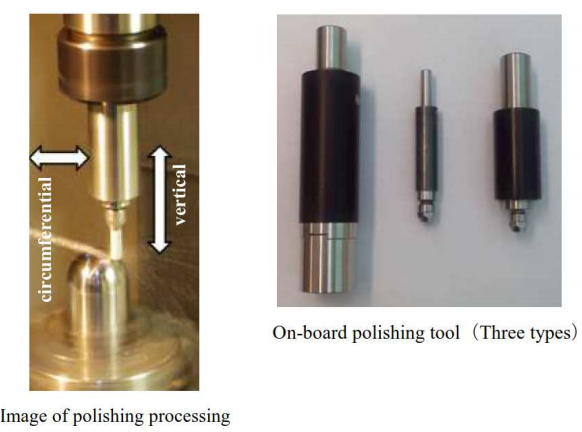

ON-BOARD POLISHING TOOL

Unmanned Die Polishing Automation of Die Polishing Processing realized on NC Machine Tools

On NC machine tools, such as machining centers, automation of polishing processing was realized by replacing a ball end mill with an on-board polishing tool attached with a special rubber bonded polishing point (Hybrid Rabin) after machining a metal surface with the mill to a desired shape.

The advantage of the On-board Polishing Tool is that the vertical and circumferential tracking functions enables the tip of the polishing point to follow the shape of a pre-machined workpiece, making it possible to polish planes, three-dimensional freely curved surfaces and the vertical walls of dies.

This product consists of ON-BOARD POLISHING TOOL and HYBRID RABIN.

1) ON-BOARD POLISHING TOOL

[Advantage]

ON-BOARD POLISHING TOOL realizes the automation of die polishing processing by attaching it to the spindle chuck of NC machine tools, such as a machining center. It requires no new capital investment, such as purchasing a special-purpose machine, and provides cheap polishing processing in spite of its simple construction.

The largest advantage of the ON-BOARD POLISHING TOOL with a tracking function is the realization of mirror face processing of nano-millimeter (nm) order using only fixed abrasive grains without using separate grains by making the end surface of a polishing point follow the shape of the surface subjected to pre-machining, such as cutting to remove tool marks generated by pre-machining planes, three-dimensional freely curved surfaces and vertical walls after this tool is combined to the later-mentioned HYBRID RABIN.

[Specification]

Three types of the ON-BOARD POLISHING TOOL are available, namely the standard and small size specifications with a vertical tracking function, and the vertical wall-targeted collet chuck specification with vertical and circumferential tracking functions.

(1) In the standard specification, a head can be replaced (polishing point chuck dia. 3 or 6 mm) so that a large diameter polishing point can be attached.

(2) In the small size collet chuck specification, a spring collet restricts runout so that a small diameter polishing point can be rotated at high speed to increase its circumferential speed.

(3) The vertical wall-targeted collet chuck specification provides our epoch-making new products with a circumferential tracking function added to a vertical tracking function capable of polishing even vertical walls.

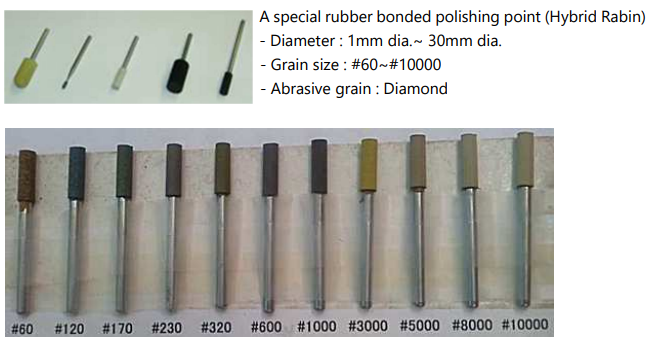

2) HYBRID RABIN

[Advantage]

Advantage of HYBRID RABIN is to provide even polishing tool marks and improved surface roughness without leaving deep polishing scratches by suitably combining the elastic and flexible rubber characteristics and the diamond abrasive grains. In addition, continuous work is possible without paying attention to clogging, and cutting quality is not deteriorated even after blackening of polishing point surface.

[Specification]

– Polishing point diameter: 1 dia.~30 dia.

– Polishing point number count: #60~#10000

– Rubber hardness: JIS durometer A scale 95

– Diamond abrasive grain: Degree of concentration 100

– Polishing point shaft: Made of stainless steel (can be cut by hacksaw)

Unmanned Tool for Die Polishing Processing

Unmanned tool for die polishing processing ON-BOARD POLISHING TOOL (‘Super’ Craftsmanship Parts Grand Prize “Mechanical Parts Award” 2013 received) is installed to a collet at the tip of the spindle of NC machine tools, such as a machining center to perform polishing processing by the rotating motion of the spindle while pressing HYBRID RUBBING (elastic rubber bonded diamond polishing point) attached to the tip of the ON-BOARD POLISHING TOOL onto a workpiece surface at a constant pressure.

ON-BOARD POLISHING TOOL with a tracking function combined with HYBRID RABIN having elasticity and flexibility realized as far as mirror face processing by making the end surface of a polishing point follow the shape of a die pre-machined by cutting and removing tool marks generated by pre-machining planes, three-dimensional freely curved surfaces and vertical walls.

The introduction effect of this product is as follows:

– Variability of die surface roughness generated by manual polishing is eliminated and quality is stabilized.

– Machining conditions can be digitized and standardized, enabling skill transfer.

– Automatic operation in the night enables to shorten a work period.

– Since the involvement in the outsourcing of polishing work, the education of craftsman and the improvement of skill are not required, cost reduction can be realized.Zirco Knight

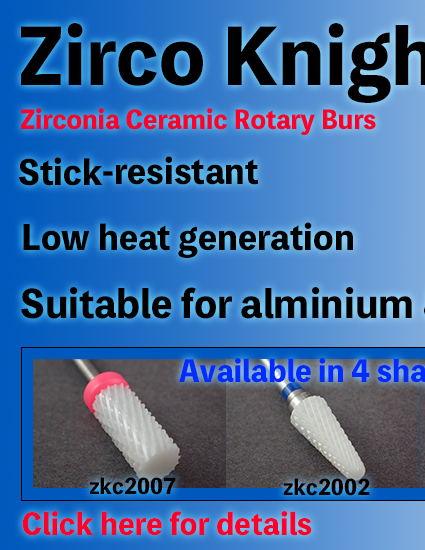

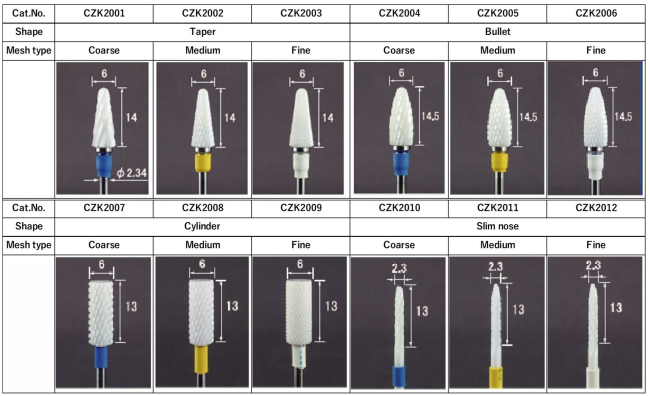

Zirconia Ceramic Rotary Burs

Zirco Knight is made of Zirconia Ceramic that is used as the material of artificial diamond.

The hardness is very high and the heat resistance is excellent but the surface is very smooth.

Therefore, the cut dust is hardly adhered to the head of Zirco Knight. Furthermore, even if it is used for a long time, it is not heated and can smoothly grind without melting.In comparison with the Carbide burs, the finished surface by Zirco Knight is smoother than one machined by Carbide burs.

Moreover, Zirco Knight is not almost clogged with the aluminum dust when cutting the aluminum materials.

In the hardness, Zirco Knight is nearly the Tungsten Carbide and the strength is also very high. As one of the advantages, it is possible to wash the head part of Zirco Knight with the water.

In the line-up, we are preparing 4 shapes such as “Taper”, “Bullet”, “Cylinder” and “Slim nose”.

The available mesh size is “Coarse”, “Medium” and “Fine” as follows.

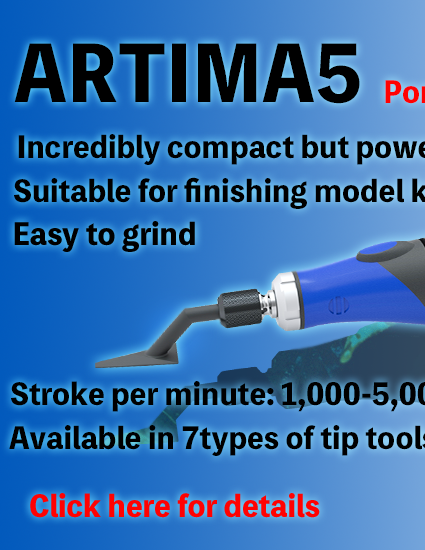

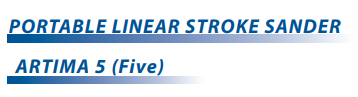

This is the portable Electric file and 3.0 mm stroke run back and forth. The filing work can be done smoothly & speedily by the light-weight and compact body.

The stroke speed can be adjusted in the range of 1,000 to 5,000 stoke per minute with the Speed Adjustment Wheel on the body.

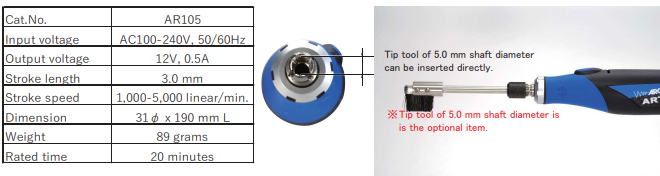

Depending on the work contents and applications, the various tip tools (7 types) are assorted as the standard accessories.

ARTIMA 5 is suitable for the delicate work and finishing work to the laminted traces of 3D printing models and bridge mark.

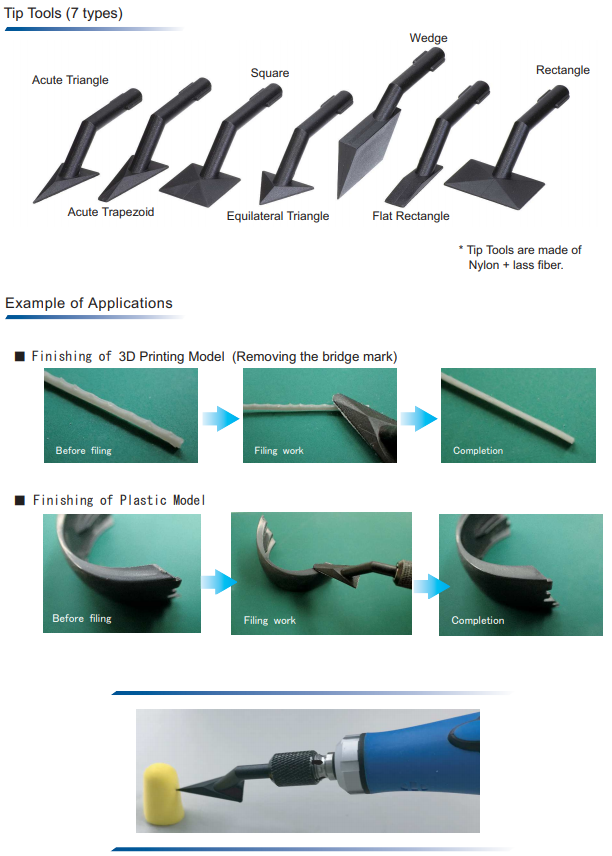

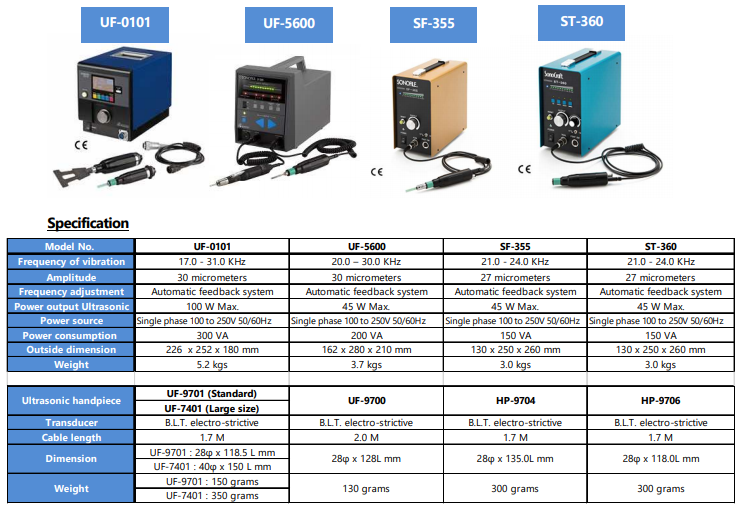

ULTRAFORM SERIES LINE-UP

Features

UF-0101

(1) Maximum output power is 100W and this is the most powerful model in our product range and high-grade type. Rough polishing and Grinding can be made aggressively.

(2) On the other hand, Ultra-fine polishing can be done in NANO function as the special function. In NANO function, the amplitude output value can be adjusted in the Ultra-micro range under 1 micro meter. NANO function is suitable for the ultra-fine polishing and the manual delicate work. The delicate polishing work that was possible only by hand work can be made with UF-0101.

(3) We are preparing 2 types of the hand pieces for UF-0101, one is the Large-sized hand piece No. UF-7401 is very powerful. Another type is very light and compact sized hand piece No.UF-9701.

(4) User-friendly operation screen is available therefore it is very easy to operate it.UF-5600

(1) Long-selling and most popular model. This is one of our best selling items.

(2) The strong point is that there are two output sockets for (1) Ultrasonic hand piece and (2) DC motor hand piece in one controller (oscillator)

(3) You can operate the ultrasonic functions and DC motor functions.

(4) The maximum output power is 45W.SF-355

(1) SF-355 is the basic and entry-level machine.

(2) It is very simple and easy operation type.

(3) Maximum output power is 45W.ST-360

(1) ST-360 is the Multipurpose Ultrasonic Finishing Machine.

(2) You can use it as the Ultrasonic polishing machine if you attach the New Super Stone.

(3) You can use it as the simple Ultrasonic cutter if you change the tool holder and the optional blade.

(4) You can also use it for the geological survey and the fossil cleaning as we are preparing the optional tools. If attaching the curved tools which the tip is bent, it can rake out the extra soil and can dig a hole at pin point.

(5) It is suitable for Removal of the pattern cut-resist film on the printed circuit board (PCB).

(6) Maximum output power is 45W.Applications

(1) As the main application, it removes the machined deformation layer on the surface formed by the electric discharge machining (EDM) in the Mold & Die.

(2) The finishing polishing can be made on the cavity surface.

(3) It can be used for the repair of the Mold & Die.Additionally,