Diamond Lapping/Polishing sheet POLYMOND

POLYMOND is the special abrasive diamond sheet which is stirred and mixed with diamond grits and the highest heat-proof Polyimide resin for ultra precision lapping / polishing.

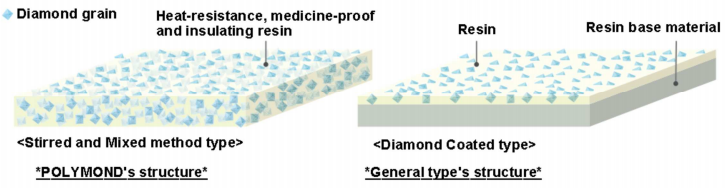

What’s the difference between the general sheet (coating type) and POLYMOND ?

The difference is the manufacturing method and structures as follows.

The manufacturing method for POLYMOND is the “Stirred and Mixed method”, Diamond grits are mixed and stirred with Polymide, a resin highly resistant to high heat and chemicals.

General type sheet (diamond coated type) is used up when grits coated on the surface are worn out.

On the other hand, the “Stirred and Mixed method” type sheet can contain grits within the resin.

Therefore, you will be able to use up the POLYMOND sheet from top to bottom.

Advantage

1) Diamond grits are combined with high strength and heat-resistance Polyimide resin by using a new technique of stir and mixture in one body. The grit maintaining force is remarkably strong, gives longer life and lower in cost performance.

2) Because of the high strength and high heat-resistance, the sheet itself has large flexional strength high elasticity and high tensile strength.

3) POLYMOND shows excellent effect on polishing hard-but-brittle materials.

4) Because of high strength and high heat-resistance of Polyimide resin, the heat-resistance of

5) POLYMOND is remarkable and there is rarely any thermal change seen under about 200ºc. POLYMOND can bear heavy duty.

6) By using the POLYMOND, it is easy to make the rough polishing to perfect mirror finishing.

7) POLYMOND can easily cut by a cutter or scissors.

Applications

1) Finishing the tungsten carbide and alloy steel mold.

2) Finishing the ceramic parts.

3) Finishing the optic fiber and glass products.

4) Mirror finishing the gemstone such as the crystal and sapphire.

5) Finishing the free-curved surface of irregular shaped products.

6) Dirt removing the carbide and ceramic.