Workfinisher

Workfinisher is the ideal product for deburring the molded parts made of the hard plastics containing talk, carbon fiber and glass filled resin etc., It is suitable for deburring and chamfering non-ferrous metal such as copper, aluminum and brass products.

-

Work Finisher

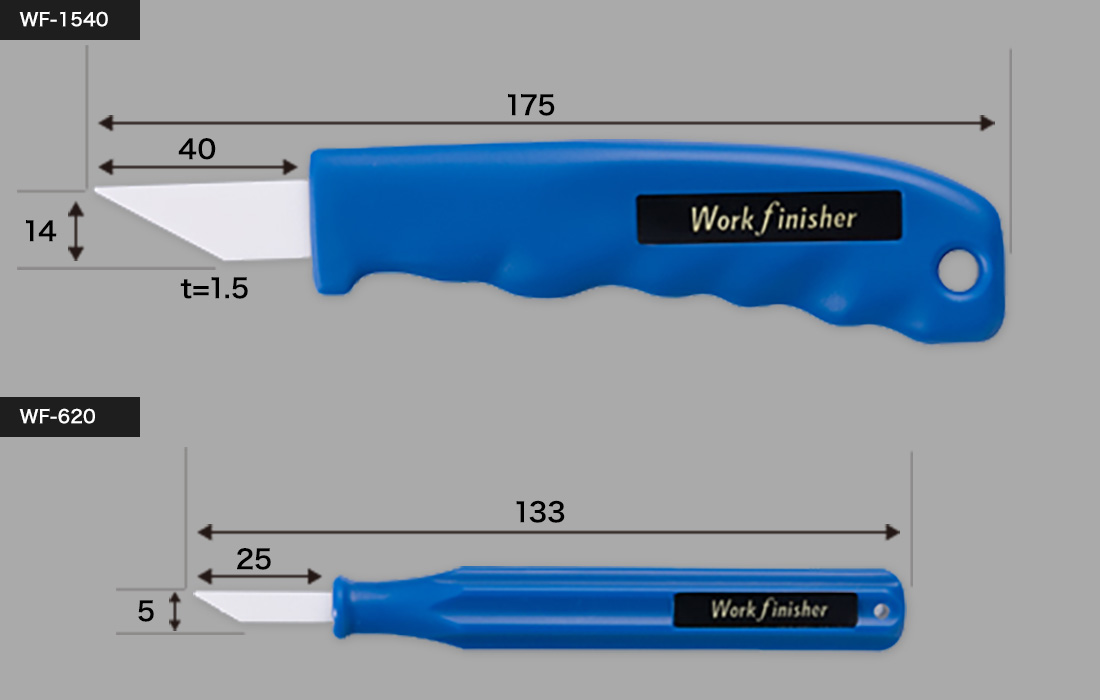

Large model No. WF-1540 / Small model No. WF-620

Ideal for curved and complicated shapes; Excels on ultra-hard resins like galss-fiber, carbon-fiber and talc filled plastics. Also it can be used on soft metals like aluminum, copper and brass.

Ideal for curved and complicated shapes; Excels on ultra-hard resins like galss-fiber, carbon-fiber and talc filled plastics. Also it can be used on soft metals like aluminum, copper and brass. -

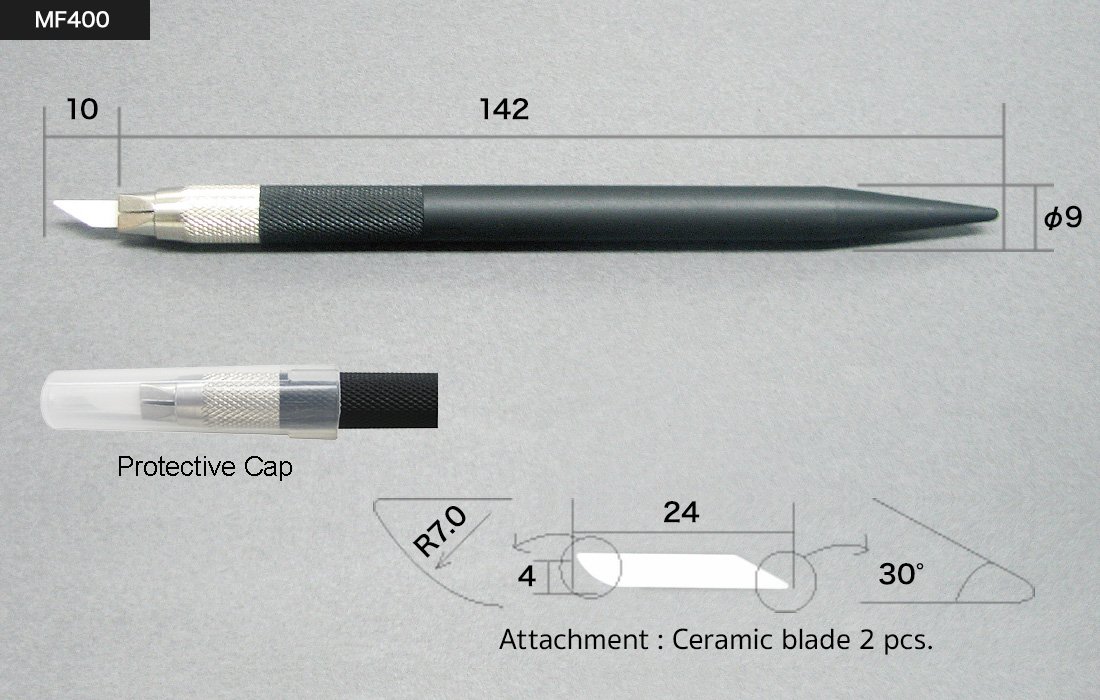

Micro Finish

Precision Deburring Hand Tool No. MF400

Ideal for surface finishing the plastics molding parts, removing fine burrs on the precision parts and chamfering.

Ideal for surface finishing the plastics molding parts, removing fine burrs on the precision parts and chamfering. -

eco Finish

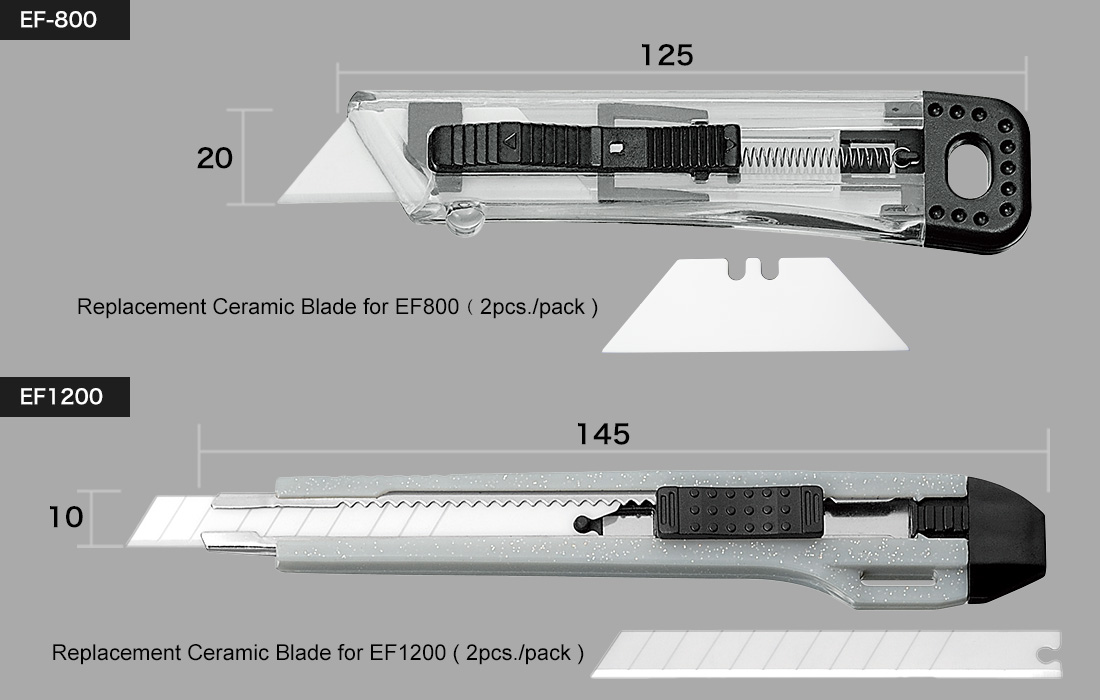

Retractable Ceramic Blade Deburring Tool No. EF800

As the advantage, it is possible to replace the ceramic blade by new one easily

As the advantage, it is possible to replace the ceramic blade by new one easily

when the ceramic blade is worn down or broken. It is suitable for deburring

fine burrs and chamfering the plastic molding, copper, aluminum and brass products. -

eco Finish

Snap-off Ceramic Blade Deburring Tool No. EF1200

Even if the ceramic blade is worn down, it is possible to use it continuously

Even if the ceramic blade is worn down, it is possible to use it continuously

by breaking each blade along the grooves on the ceramic blade.

Can be used like the utility knife or box cutter but very safe.

It is suitable for deburring fine burrs and chamfering the plastic molding,

copper, aluminum and brass products.

Feature

-

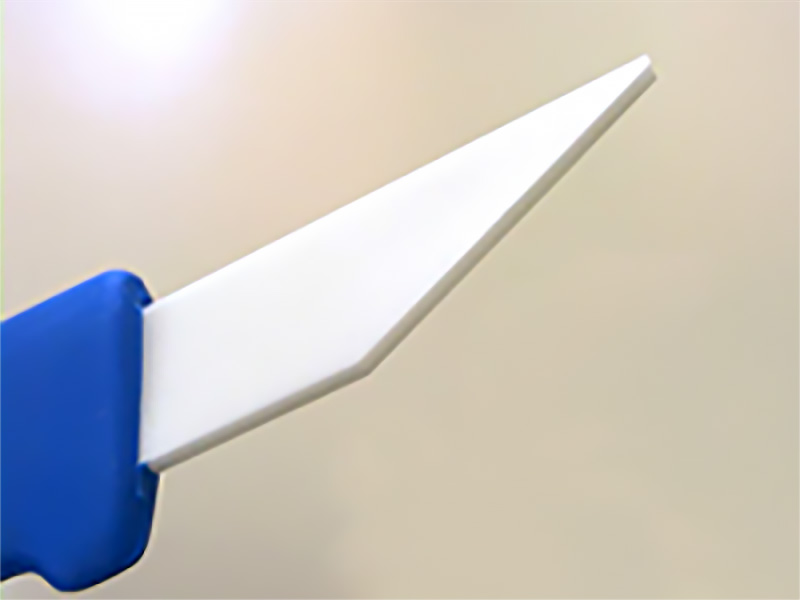

Space age ceramics make safe deburring possible because of Workfinisher’s unique non-blade like edge. (No sharp edge)

Space age ceramics make safe deburring possible because of Workfinisher’s unique non-blade like edge. (No sharp edge) -

Deburrs hard plastics effortlessly withou the fear of cutting your hand or fingers in the process. (very safe knife)

Deburrs hard plastics effortlessly withou the fear of cutting your hand or fingers in the process. (very safe knife) -

Can be used for surface finishing the plastics molding parts, very small, very confined areas, narrow, cocave area or complex portion.

Can be used for surface finishing the plastics molding parts, very small, very confined areas, narrow, cocave area or complex portion. -

Incline the ceramic blade on the workpieces at an angle of 30-70 degrees depending on the amount of flash (burr) to be removed and pull toward yourself.

Incline the ceramic blade on the workpieces at an angle of 30-70 degrees depending on the amount of flash (burr) to be removed and pull toward yourself.

-

WF-1540 / WF-620

WF-1540 : 56g

WF-620 : 20g -

MF400

MF400 : 14g

*Excluding the weight of blade.

Blade thickness : 0.4mm

Blade weight : 0.2g

*Please use only Argofile blade No.MFC3001. -

EF800 / EF1200

[EF800]

Blade thickness : 0.8mm

Replacement Ceramic Blade for EF800(2pcs./pack)

[EF1200]

Blade thickness : 0.8mm

Replacement Ceramic Blade for EF1200(2pcs./pack)

Test data

A : Exceptional deburring power compared with conventional steel deburring tools.

B : Similar deburring power as steel deburring tools; with safe and longer working life.

| Workpieces | Judge |

|---|---|

| Nylon : Glass 30% / Talc 30% | A |

| PPS : Glass 30% / Talc 30% | A |

| PBT : Glass 30% | A |

| PC : Glass 30% | A |

| PMMA | A |

| ABS | A |

| GP | A |

| Workpieces | Judge |

|---|---|

| HIPS | A |

| AS | A |

| Melamine | A |

| Phenol | A |

| PP : Glass 30% | A |

| HDPE | B |

Caution

- Avoid heavy impact to the ceramic blade.

- Impact resistant eye protection such as safety glasses must be worn when using this tool.

- Protect fingers, hands, with gloves from an unforeseen accident on working.