Sintered Vents

Unique product made by Powder Metallurgy Process

Sintered Vent is produced by applying sintering process of powder metals and has many paralleled, straight micro pores that allow air/gas purge.

It is also called air vent or gas vent and used as gas purging vent during aluminum casting and resin molding. If a certain level of air and/or gas, which comes from raw materials, remains inside the cavity at the time of injection of melted resin or casting of aluminum alloy under low pressure, it defects the finished products. Our vent helps purging those air and gas during molding process.

-

Applications

1. Degasing for low-pressure casting or plastic molding

1. Degasing for low-pressure casting or plastic molding

2. Fluid damper or silencer

3. Fluid jet nozzle

4. Pivot ball bearing or bearing for a sliding section

5. Heat exchanger

6. Fluid catalyst

7. Heat sink material(high temperature conduction, low temperature inflation)

8. Electric contacts and electrode materials

9. Beam screen(image mask)

10. Stabilizer for superconductive material

Featuers

-

1.The pore diameter is available within range of 0.01 to 5 mm.(There are some restrictions, depending on the material used.)

-

2.Different pore diameters can be combined, and there is a wide variety of choice in the number of pores (1 to 1,000,000) and the percentage of voids (this means the ratio of the pore area to the effective sectional are; up to 95%).

-

3.Applicable materials include Fe, Cu, Mo, Ti, Al, SUS, sealing alloy and cementer carbide.

-

4.By surface treatment, the properties can be changed and compounded into ceramic characteristics such as in carbide or nitride.

-

5.The pore inner wall is a spiral, ensuring a large specific surface area.

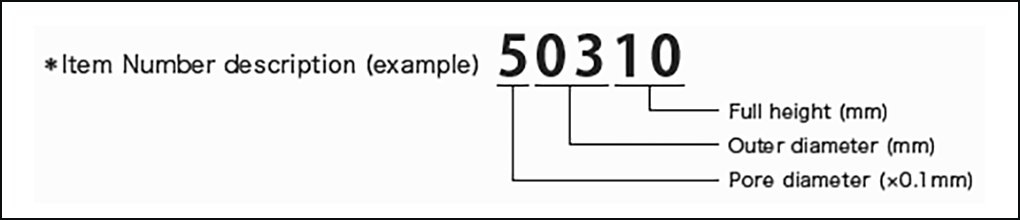

Specification of Sintered Vent

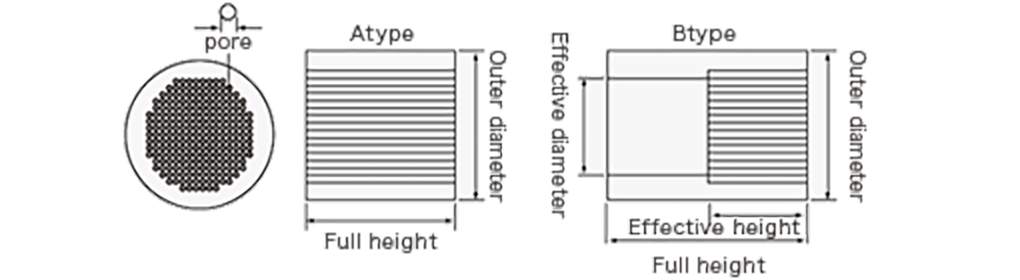

A type

P–type / W-type

B type

P–type / W-type

| P-type vent [Material: Fe-Cu-C type] | ||||||

| Type | Code No. | Outer diameter (mm) |

Full height (mm) |

No.of pores |

Pore dia (mm) |

Porosity (%) |

|---|---|---|---|---|---|---|

| A | 50310 | 3 | 10 | 39 | 0.5 | 60 |

| A | 50410 | 4 | 10 | 39 | 0.5 | 55 |

| A | 50510 | 5 | 10 | 61 | 0.5 | 45 |

| A | 50610 | 6 | 10 | 61 | 0.5 | 40 |

| A | 50615 | 6 | 15 | 61 | 0.5 | 40 |

| A | 50810 | 8 | 10 | 96 | 0.5 | 35 |

| A | 50815 | 8 | 15 | 96 | 0.5 | 35 |

| A | 51010 | 10 | 10 | 200 | 0.5 | 34 |

| A | 51015 | 10 | 15 | 200 | 0.5 | 34 |

| A | 51210 | 12 | 10 | 200 | 0.5 | 31 |

| A | 51215 | 12 | 15 | 200 | 0.5 | 31 |

| A | 51415 | 14 | 15 | 341 | 0.5 | 35 |

| A | 51615 | 16 | 15 | 341 | 0.5 | 32 |

| A | 51815 | 18 | 15 | 553 | 0.5 | 33 |

| A | 52015 | 20 | 15 | 553 | 0.5 | 33 |

| A | 52815 | 28 | 15 | 973 | 0.5 | 30 |

| A | 30510 | 5 | 10 | 96 | 0.3 | 30 |

| A | 30515 | 5 | 15 | 96 | 0.3 | 30 |

| A | 30610 | 6 | 10 | 96 | 0.3 | 29 |

| A | 30615 | 6 | 15 | 96 | 0.3 | 29 |

| A | 30810 | 8 | 10 | 200 | 0.3 | 28 |

| A | 30815 | 8 | 15 | 200 | 0.3 | 28 |

| A | 31010 | 10 | 10 | 341 | 0.3 | 31 |

| A | 31015 | 10 | 15 | 341 | 0.3 | 31 |

| A | 31210 | 12 | 10 | 341 | 0.3 | 28 |

| A | 31215 | 12 | 15 | 341 | 0.3 | 28 |

Tolerance of outer diameter +0.03 to 0.08 Length ±0.5

| P-type vent [Material: Fe-Cu-C type] | ||||||||

| Type | Code No. | Outer diameter (mm) |

Full height (mm) |

No.of pores |

Pore dia (mm) |

Porosity (%) |

Effective height (mm) |

Effective diameter (mm) |

|---|---|---|---|---|---|---|---|---|

| B | 201010 | 10 | 10 | 880 | 0.2 | 35 | 5 | 6 |

| B | 100810 | 8 | 10 | 880 | 0.1 | 29 | 5 | 5.5 |

| B | 101010 | 10 | 10 | 880 | 0.1 | 29 | 5 | 5.5 |

| B | 050610 | 6 | 10 | 880 | 0.05 | 18 | 5 | 3.5 |

| B | 050810 | 8 | 10 | 880 | 0.05 | 18 | 5 | 3.5 |

| B | 051010 | 10 | 10 | 880 | 0.05 | 18 | 5 | 3.5 |

| B | 030610 | 6 | 10 | 880 | 0.03 | 13 | 5 | 2.5 |

| B | 030810 | 8 | 10 | 880 | 0.03 | 13 | 5 | 2.5 |

| B | 031010 | 10 | 10 | 880 | 0.03 | 13 | 5 | 2.5 |

Tolerance of outer diameter +0.03 to 0.08 Length ±0.5

| W-type vent [Material: Fe-Ni-Cr Mo type] | ||||||||

| Type | Code No. | Outer diameter (mm) |

Full height (mm) |

No.of pores |

Pore dia (mm) |

Porosity (%) |

Effective height (mm) |

Effective diameter (mm) |

|---|---|---|---|---|---|---|---|---|

| A | W200610 | 6 | 10 | 169 | 0.2 | 27 | 10 | 5 |

| A | W200810 | 8 | 10 | 288 | 0.2 | 27 | 10 | 6.5 |

| B | W201010 | 10 | 10 | 180 | 0.2 | 23 | 3 | 5.5 |

| A | W100110 | 1 | 10 | 7 | 0.1 | 19 | 10 | 0.6 |

| A | W100210 | 2 | 10 | 55 | 0.1 | 19 | 10 | 1.7 |

| A | W100310 | 3 | 10 | 76 | 0.1 | 19 | 10 | 2 |

| A | W100410 | 4 | 10 | 76 | 0.1 | 19 | 10 | 2 |

| B | W100510 | 5 | 10 | 76 | 0.1 | 19 | 3 | 2 |

| B | W100610 | 6 | 10 | 76 | 0.1 | 19 | 3 | 2 |

| B | W100810 | 8 | 10 | 300 | 0.1 | 19 | 3 | 4 |

| B | W101010 | 10 | 10 | 690 | 0.1 | 19 | 3 | 6 |

| B | W101210 | 12 | 10 | 1200 | 0.1 | 19 | 3 | 8 |

| B | W101510 | 15 | 10 | 1900 | 0.1 | 19 | 4 | 10 |

| B | W102010 | 20 | 10 | 4300 | 0.1 | 19 | 4 | 15 |

| A | W050110 | 1 | 10 | 43 | 0.05 | 25 | 10 | 0.65 |

| A | W050210 | 2 | 10 | 225 | 0.05 | 22 | 10 | 1.7 |

| A | W050310 | 3 | 10 | 225 | 0.05 | 25 | 10 | 2 |

| A | W050410 | 4 | 10 | 225 | 0.05 | 25 | 10 | 2 |

| B | W050510 | 5 | 10 | 400 | 0.05 | 25 | 3 | 2 |

| B | W050610 | 6 | 10 | 400 | 0.05 | 25 | 3 | 2 |

| B | W050810 | 8 | 10 | 1600 | 0.05 | 25 | 3 | 4 |

| B | W051010 | 10 | 10 | 3600 | 0.05 | 25 | 3 | 6 |

| B | W051210 | 12 | 10 | 6400 | 0.05 | 25 | 3 | 8 |

| B | W051510 | 15 | 10 | 10000 | 0.05 | 25 | 4 | 10 |

| B | W052010 | 20 | 10 | 20000 | 0.05 | 22 | 4 | 15 |

| A | W030110 | 1 | 10 | 70 | 0.03 | 25 | 10 | 0.5 |

| A | W030210 | 2 | 10 | 280 | 0.03 | 25 | 10 | 1 |

| A | W030310 | 3 | 10 | 630 | 0.03 | 25 | 10 | 1.5 |

| A | W030410 | 4 | 10 | 1120 | 0.03 | 27 | 10 | 2 |

| B | W030510 | 5 | 10 | 1120 | 0.03 | 27 | 2 | 3 |

| B | W030610 | 6 | 10 | 1120 | 0.03 | 27 | 2 | 3 |

| A | W020210 | 2 | 10 | 224 | 0.02 | 9 | 10 | 1.8 |

| A | W020310 | 3 | 10 | 532 | 0.02 | 9 | 10 | 2.3 |

| A | W020410 | 4 | 10 | 750 | 0.02 | 7 | 10 | 3.2 |

Tolerance of outer diameter +0.05 Length ±0.2