Daiwa Rabin

Daiwa Rabin is a rubber grinding stone.

This rubber grinding stone is an ideal for "cut", "polish", and "last long"!

For grinding and finishing of metal products

Dramatic improvement in processing efficiency and work environments

* “Daiwa Rubin” is registered trademark of elastic abrasive products for both grinding and polishing made by Daiwa Chemical Industries’ original method of bonding abrasive particles with specially formulated synthetic rubber.

Unparalleled Finish Quality

Grind finely and polishes effectively

Daiwa Rubin abrasives contain an original elastic bonding material. Unlike conventional hard grinding stones, the Daiwa Rabin stones adapt well to the materials processed and maintain clean grinding surfaces for lustrous, uniform finishes.

The use of the elastic abrasive material developed originally by Daiwa results in fine grinding and effective polishing to provide superb finish quality unmatched by conventional grinding stones.

| Comparison of surface roughness | |

|---|---|

Intermediate processing with ordinary abrasive material |

Intermediate processing with the Daiwa Rubbing abrasive |

Dramatic Labor Saving and High-Efficiency Operation

Covering two processes of grinding and polishing

The Daiwa Rabin abrasive products adapt to a broader range of processing than ordinary abrasive materials.

A single Daiwa Rubbing product can be used for both grinding and polishing. As a result, our products significantly reduce labor and improve process efficiency.

High polishing quality in intermediate grinding and polishing processes results in a superior finish. The Daiwa Rabin abrasives produce less dust particles than ordinary grinding stones, thus providing a cleaner work environment which has earned high acclaim from users.

A Wide Range of Formulation to Meet All Metal Polishing Needs

A selection of both hardness and strength, tailor made for every polishing application

A wide range of products with different hardness and bonding strength are available to match the type of metal material to be processed. Our elastic abrasive stones are soft to the touch and produce low noise. The Daiwa Rabin abrasives are easy to use – even for beginners.

Daiwa offers 5,000 types of products. Users can select the most appropriate product in accordance with the type of processing material, polishing location and finishing surface.

Furthermore, we can supply products according to userspecified abrasive particle types, shapes and dimensions.

CAUTION

The Daiwa Rubbing abrasives have elasticity, and must be used at R.P.M.s lower than the one specified by our company. In the case of high-speed grinders, be sure to inverter the rotating speed.

The Daiwa Rubbing abrasives produce superb finish at a low rotating speed.

Product Types and Shapes

Shaft-equipped type, flat type, offset type, square type, round bar type, sheet type, belt type, cup type, cut type, special shapes

Bonding materials

| Type: 3 types (CM, OX and UN) | |

|---|---|

| CM type | Daiwa chemical Industries’ original products are made of special rubber and unique abrasive particles for both grinding and polishing. These innovative elastic abrasive products can be used to grind and polish aluminum and stainless steel without clogging the abrasive surface. |

| OX type | Provides finishes with a higher luster than CM type. This type can also be used for hairline finishes. |

| UN type | General-purpose type for easy use. This type is suitable for chamfering and other processing that does not require stone elasticity. |

| CMK | CM type for use with high-speed grinders. Available in limited sizes with coarse, medium and fine levels of surface roughness. |

Types of Abrasive Particles and Available Combination

| Abrasive particles | |||

| Name | Code | Material | Applications |

|---|---|---|---|

| Alundum | A | Brown dissolved alumina abrasive material | Suitable for ordinary steel materials such as mild steel and semi-mild steel. Can also be used effectively to prevent surface scorches in processing stainless steel and hardened steel. |

| White alundum | WA | White dissolved alumina abrasive material | |

| Carborundum | C | Black silicon carbide abrasive material | Suitable for cast iron and nonferrous metals such as aluminum and copper alloys. |

| Carborundum White alundum |

CAW | C + WA mix | General-purpose type. Provides superb cutting performance for special steels with hard surface. |

| Green carborundum | GC | Green silicon carbide abrasive material | General-purpose type. Provides superb cutting performance for special steels with hard surface. |

| Combinations of abrasive particle and | |||||

| WA | A | C | CW | GC | |

|---|---|---|---|---|---|

| CM43,43/4,55,CMP66 | ○ | ||||

| OX12,14,22,44,45,55,66 | ○ | ○ | ○ | ○ | ○ |

| UN58,77,89 | ○ | ○ | ○ | ○ | ○ |

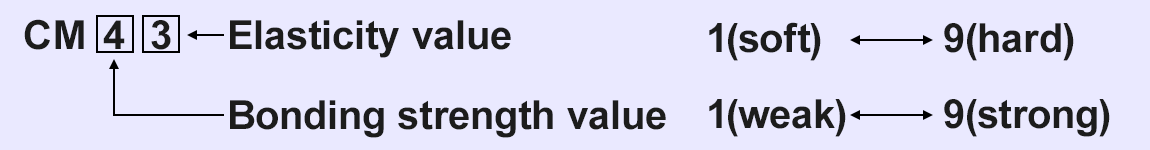

Indication of bonding strength and elasticity

CM type: WA

Particle size limited to #46, #60, #80, #100, #120, #150, #180, #220, #240 and #320.

OX and UN types: WA, A, C, CW and GC Particle size ranging from #24 to #10000 Mixing of diamond particles also possible.

External feature

The CM type contains yellow particles. #80(red), #120(blue), #180(yellow), #220(green), others(brown)

All OX type products are dark green. The UN type is either light brown or gray.

* The product color changes to brown after approximately six month, but this discoloration does not denote quality degradation.

Precaution

Please note that product dimensions may vary slightly due to expansion and contraction of the rubber material.

* Since the bonding material is more flexible than that used in baked grinding stones and resinoid stones, the current JIS bonding strength testing method is not applicable. The above nine-level classification is based on our company standard.